Experimental Study on Wear Characteristics of PCBN Tool with Variable Chamfered Edge | Chinese Journal of Mechanical Engineering | Full Text

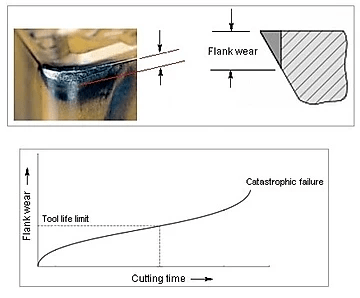

Infinity MFG - Tool wear describes the gradual failure of cutting tools due to regular operation. It is a term often associated with tipped tools, tool bits, or drill bits that are

The use of tool flank wear and average roughness in assessing effectiveness of vegetable oils as cutting fluids during turning—a critical review | The International Journal of Advanced Manufacturing Technology

![PDF] Measurement of tool flank wear with the use of white light interferometer | Semantic Scholar PDF] Measurement of tool flank wear with the use of white light interferometer | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/439e33d95214c8fec625ab27645b12f3f8f3a585/2-Figure1-1.png)

![Schematic of flank and crater wear and their measurements [1]. | Download Scientific Diagram Schematic of flank and crater wear and their measurements [1]. | Download Scientific Diagram](https://www.researchgate.net/publication/321036401/figure/fig2/AS:560281380024326@1510592898972/Schematic-of-flank-and-crater-wear-and-their-measurements-1.png)

![Typical wear patterns according to ISO 3685 [2]. | Download Scientific Diagram Typical wear patterns according to ISO 3685 [2]. | Download Scientific Diagram](https://www.researchgate.net/publication/283025373/figure/fig1/AS:297043131158531@1447832009291/Typical-wear-patterns-according-to-ISO-3685-2.png)